At Proeliator, we believe that a properly cleaned and lubricated firearm will not only keep your firarm running for years but is also a safer, more reliable, and more accurate firearm to use.

When is the last time you’ve completely disassembled your firearm, performed a thourough inspection, deep cleaned, and lubricated your firearm?

For most people, the answer is “Never!.”

Most times cleaning consists of merely running a bore snake down the barrel, applying some oil to the necessary parts, and wiping down the gun. This misses getting into those hard-to-reach areas of the firarm’s mechanics which can adversely affect the firearm’s operation over time. This potentially (dare I say definitely) will affect the safety and accuracy of the firearm.

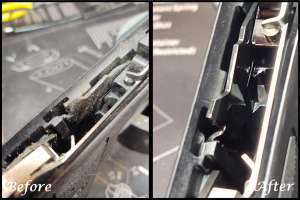

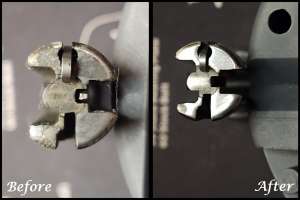

Do you think you can get your gun this clean using traditional methods?

Click on any image to zoom in.

HANDGUNS

$60.00 / firearm

All late model pistols or revolvers

RIFLES/SHOTGUNS

$80.00 / firearm

All late model rifles, single-barreled shotguns, short-barreled rifles, AR-style pistols and pistol caliber carbines.

DB SHOTGUNS

$100.00 / firearm

All late model double-barreled shotguns (over and under or side-by-side)

ANTIQUE FIREARMS

$150.00 / firearm

NOT ‘Antique’ in the legal sense of the word, but practical; any firearm manufactured prior to 1960.

* These are base prices for standard firearms not requiring special cleeaning or handling.

ULTRASONIC Deep Cleaning process

Step 1

Step 2

All parts are initially inspected for excessive carbon fouling or damage.

Step 3

The parts are then placed into our state-of-the-art Infante Ultrasonic Gun Cleaning System.

The parts are ultrasonically cleaned using Infante’s

Sonic Tonic™ Precision Ultrasonic Cleaning Concentrate.

Step 4

Upon completion of the ultrasonic cleaning cycle, the parts are again inspected.

Step 5

Any parts not completely cleaned are manually scrubbed with a brush

and then placed back into the ultrasonic cleaner for another cycle.

Step 6

Once the parts are completely cleaned by the ultrasonic cleaner, they are rinsed with hot water to remove the excess cleaning solution and then blown dry with compressed air.

Step 7

The parts are then inspected again in the case where excessive

fouling was covering up mechanical issues.

The advent of a high-resolution digital borescope inspection camera allows inspection at great detail.

Step 8

The parts are then placed into the special water-displacing

lubrication tank and ultrasonically lubricated.

The parts are ultrasonically lubricated using Infante’s Sonic Lube™ Water Displacing Metal Protectant.

Step 9

Once the ultrasonic lubrication process completed, the parts are again dryed with compressed air.

Step 10

Again with the aid of a borescope inspection camera, the parts are lubricated

with a performance lubricant in accordance with manufacturer recommendations.

Proeliator uses Lucas Oil’s Extreme Duty Gun Oil and/or Extreme Duty Gun Grease.

Step 11

Finally, the firearm is reassembled and checked for safe and reliable operation

and then wiped down to remove any fingerprints, etc.

Conditions and exclusions

- Proeliator reserves the right to refuse any work, or work we deem would render a firearm unsafe

- A liability waiver MUST be signed for this service

- We DO NOT clean optics; they will be removed prior to cleaning then reattached upon conclusion

- We DO NOT remove or deactivate firearm safeties

- We DO NOT test fire your firearms (Heck, we just cleaned it! That’s your job!)

- We DO NOT service or clean air pistols, airsoft guns, or paintball guns or any other ‘non gun’

- There will be a $25.00 surcharge for firearms containing Cosmoline™ or other similar petroleum-based rust and corrosion inhibiting grease

- There will be an additional surcharge to remove parts affixed with epoxy or high-strength threadlocking compound (e.g. Loctite Red, Vibra-Tite Green, Rocksett, Permatex Red, J-B Weld Red)

The difference between something good and something great is attention to detail.

Charles R Swindoll, pastor & author